Building a laminated top, like the one on this multi-purpose cart, might seem intimidating at first. There are a lot of strips to glue together. So getting a fl at, smooth surface with tight-fitting joints can be a challenge. The key to success is breaking up the process into smaller, more manageable steps. You’ll be surprised at how easy it is.

The first step in building a laminated top is selecting the right material for the strips. Since the top will see a lot of use, a durable material is a must. You could use hardwood, but cost is always a consideration. To solve both problems, I chose “two-by” Douglas fir to make the top of the cart. Besides being hard and durable, it’s relatively inexpensive and you can find it at most home centers and lumberyards. As you select your material, be sure to spend some time finding straight boards with as few knots and defects as possible. It pays to be a little choosy here. Once you get the lumber home, it’s a good idea to let it sit for a few days to acclimate to your shop. The next step is to cut the lumber to rough length. I like to start with pieces that are a few inches longer than I need. And then I rip the boards into strips, like the center boards shown in the photo. The main goal is to start with extra-wide strips. Then you can joint and plane them to end up with consistent strips ready for gluing (lower boards). Since I wanted my top about 2" thick, I ripped the strips down to 21⁄8" wide. This provides a little extra thickness for smoothing later. Once you have all the strips cut, you’ll be turning them on edge when you glue them up. This exposed edge grain provides a couple of side benefits — a tougher surface and a more stable top.

At this point, you’re ready to start gluing up strips. But the key to a fl at top is to start small. Instead of trying to glue all the strips at once, it’s better to deal with just a few at a time. It’s less hectic and you’ll end up with better results. If you have a nice flat worksurface to use for the glue-up, that’s great. But the sawhorses I used worked just as well. The first thing I did was sight across their tops and adjust them to make sure they were in the same plane. This minimizes any chance of introducing twist into the glueups. Apply glue and clamp a set of the strips together to form a small slab that’s narrow enough to run across your jointer. I also like to use a clamp across each joint line to keep the surfaces as even as possible.

After scraping off the squeezeout, flatten one face. Finally, run the section through your planer to flatten the opposite face and bring the assembly to final thickness, like you see in the lower right photo on the opposite page. It’s also a good idea to joint each edge to ensure it’s fl at, straight, and square to the surface. Then you can simply repeat this process to create as many sections as you’ll need for the top.

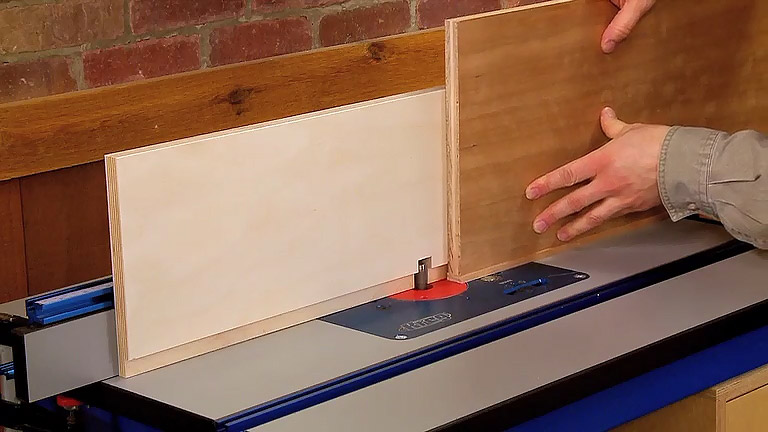

At this point, you’re ready to glue the sections together into a fullwidth top. Here again, I keep things simple. Instead of gluing up all the sections at once, I only glue two together at a time (inset above). Now comes the easy part, gluing the larger sections together to create the top. Again, clamping across the joint lines minimizes any flattening work once the glue dries. Since the top is too wide to run across a jointer (or through a planer, for that matter), any flattening will have to be done with a belt sander or hand plane. But with the steps detailed here, don’t be surprised if all you really need to do is scrape away a little excess glue. That’s all I did for the top you see here. All that’s left to do at this point is cut the top to final length. And that means trimming both of the ends straight and square. Because of the size of the top, you won’t be able to do this on your table saw. A simple solution is to use a circular saw and a straightedge clamped securely across the end.