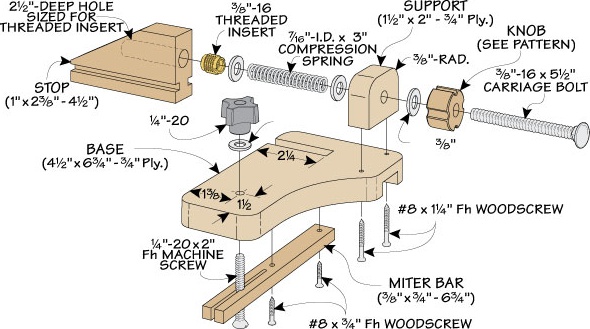

Micro-Adjust Ripping Jig

Ripping consistent, thin strips on the table saw can be a hit-or-miss proposition. This shop-made jig brings accuracy in ripping to a whole new level.

To use the jig, slide it adjacent to the saw blade so you can “zero out” the stop against the blade. Then, pull the jig back just in front of the blade and lock it down with the threaded knob.

Now, rotate the knob counterclockwise to dial in the thickness of the strip you need to cut. Slide your workpiece and rip fence over until the workpiece contacts the stop.

Finally, you’re ready to make the cut. The great thing is, you can make repeated rip cuts without a lot of setup or fuss.

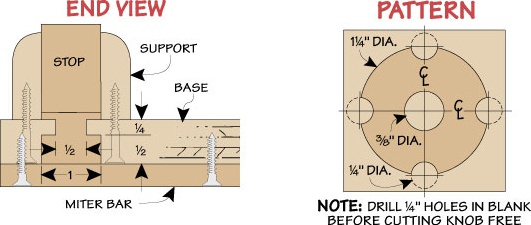

A knob can be made by drilling 4 holes in a piece of plywood before cutting it free, shown in the pattern. Each complete turn of the knob moves the stop 1/16".

The drawings in this tip show how to make all the pieces, starting with the base. A tapered stop slides along a slot in the base controlled by a shop-made knob and carriage bolt. The spring supplies constant pressure on the workpiece.