Noise from power tools is more than just a minor annoyance — long-term exposure to the noise from power tools can cause hearing loss. The first line of defense is good hearing protection, like a set of earmuffs or earplugs.

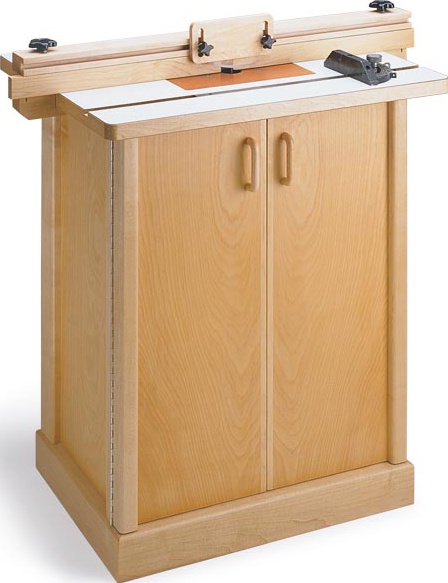

One of the simplest ways to deal with a loud tool is to contain the noise by enclosing it in a cabinet or stand. This works great for shop vacuums, air compressors, or the router table shown here. The enclosure doesn’t have to be anything elaborate, as long as it seals out as much of the sound as possible.

Note: Most tools require a source of ventilation in order to prevent heat build-up within the motor.

When it comes to stationary, beltdriven power tools, vibration is one of the biggest contributing factors to noise. The first step in reducing vibration is to make sure the pulleys are aligned and securely attached to their shafts. If this doesn’t alleviate the problem, try replacing the stock V-belt and die-cast pulleys with a link belt and machined steel pulleys, like those shown below. These components run smoother than the ones that most likely came with your tool and they can greatly reduce the amount of vibration.

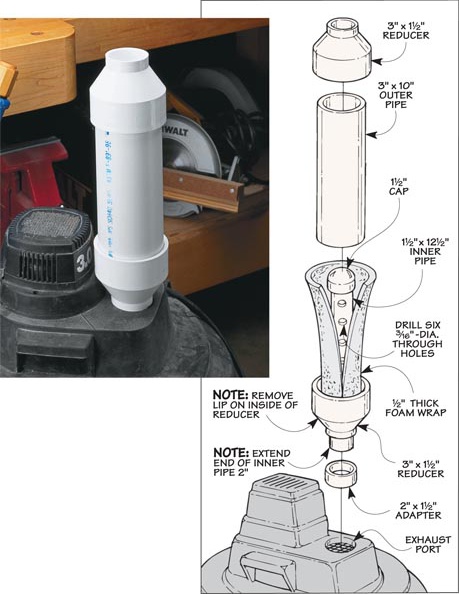

If you were to make a list of the tools that are the worst noise offenders, the shop vacuum would rank near the top. But if your shop vacuum has an exhaust port that will accept a hose, you can make a muffler that will cut the noise level almost in half. The muffler is nothing more than insulation foam housed in a PVC pipe and fitting assembly.

The concept of the muffler is simple. A layer of flexible foam insulation fits between the walls of an inner and outer pipe. The smaller inner pipe is drilled with several holes and then capped. This way, air from the vacuum is expelled through the holes and then passed into the foam. The foam dampens the sound, and then the air is forced out through a reducer at the top of the muffler. I assembled the muffler using PVC cement. Then to fit the muffler into the exhaust port of my shop vacuum, I used a simple adapter fitting around the inner pipe.

Even though there are ways to minimize tool vibration, it’s nearly impossible to eliminate it altogether. So in some cases, the next best thing is to simply isolate the vibration before it’s transferred to the tool stand. There are a couple of ways you can do this. The first method is to use isolation mounts. These are simply hard rubber cylinders that have either a threaded stud or a threaded hole at either end. The mounts are placed in between the tool and the stand.

What makes these mounts work is the fact that the mounting bolts thread into each end, rather than passing all the way through the mount. So they act like mini-shock absorbers to cushion the tool against vibration.